Release date:2012-05-23 11:02:59Click-through rate:1068

The production systems that our company has built and put into operation include an annual production of 1500 tons of granules (WDG, DF), 3000 tons of powders (WP), 3000 tons of emulsifiable concentrates (EC), and 1500 tons of suspensions (SC, OF).

At present, the specific production capacity of our company's WDG and DF is: 5T/d for extruded columnar particles, 2T/d for circular spherical particles, and 1T/d for boiling fine particles.

Production process description: Our company's WDG and DF manufacturing adopts the currently popular dry crushing wet granulation process, with the key lies in "formula, equipment, and process".

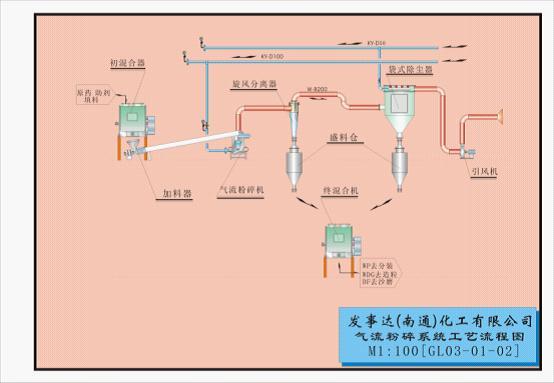

1. Crushing process: The pesticide raw powder is roughly crushed to around 100 mesh, put into the initial mixer, and additives, fillers, etc. are added. Under the action of supersonic air flow generated by compressed air inside the airflow crusher, strong collisions between material particles are achieved, resulting in a particle size of 2-10 μm Ultrafine powder,Mix evenly through the final mixer and wait for use;

2. Granulation process:

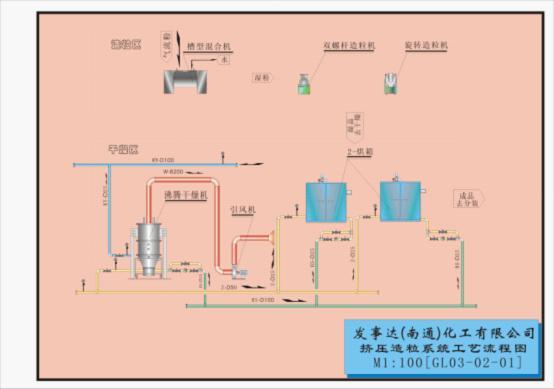

(1) Squeeze: Add an appropriate amount of water to moisten the previous ultrafine powder in the kneading machine, knead thoroughly and evenly, and then add it to the granulator for granulation; Extrusion can be divided into screw extrusion and rotary extrusion. Our company will choose reasonable granulation equipment based on the nature of the processed materials.

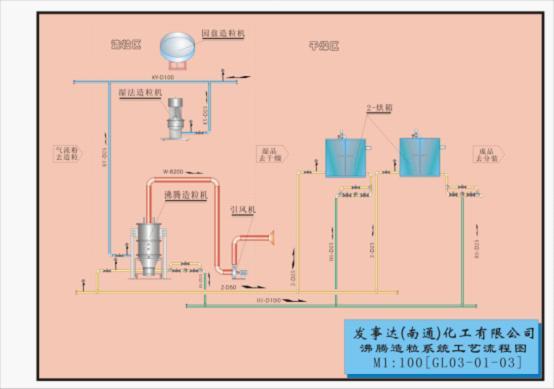

(2) Boiling or disc granulation: directly pour the previous ultrafine powder into the granulator for granulation.

3. Drying process: Dry the previous wet particles in a dryer to standard moisture content; The selection of dryers and process control have a significant impact on product quality.

4. Screening process: The previous particles are sieved in a vibrating screen to obtain standard particle size particles, which are WDG and DF finished products. The sieved products are recycled and then granulated.