Release date:2012-04-12 15:49:53Click-through rate:1035

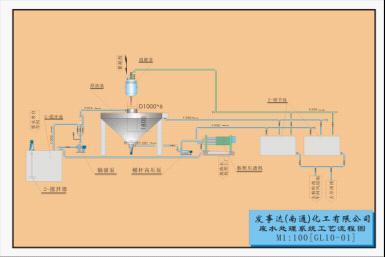

The company has a clear awareness of environmental protection and safety, and fully considers employee protection and environmental safety in the design and construction of the factory. The drainage system in the factory adopts a clean and sewage diversion system, and each production workshop has a primary wastewater collection tank and delivery pump. The factory has a dedicated wastewater treatment station. Taking the powder and particle workshop as an example, negative pressure operation is achieved in the production area. After the production exhaust and on-site dust are collected and recycled by the pulse type dust collector, they are discharged into the water washed air duct, then they are cleaned by three water curtains before being discharged; The wastewater is sent to the buffer tank in the factory area, and after flocculation, sedimentation, and regulation, it is tested to meet the discharge standards of the environmental monitoring station in the park (COD<500PPM) before being discharged into the park's sewage pipeline network; The flocculent sediment is filtered and solidified by a plate and frame filter press, and then entrusted to a solid waste treatment center for treatment.